Tools to do this mod. 5/64" drill bit. Preferably a Drill

Press, and a countersink tool.

I used M2 - screws long enough to go though the housing, that I picked

up at my local hardware store. They need to be a little longer than

1/2".

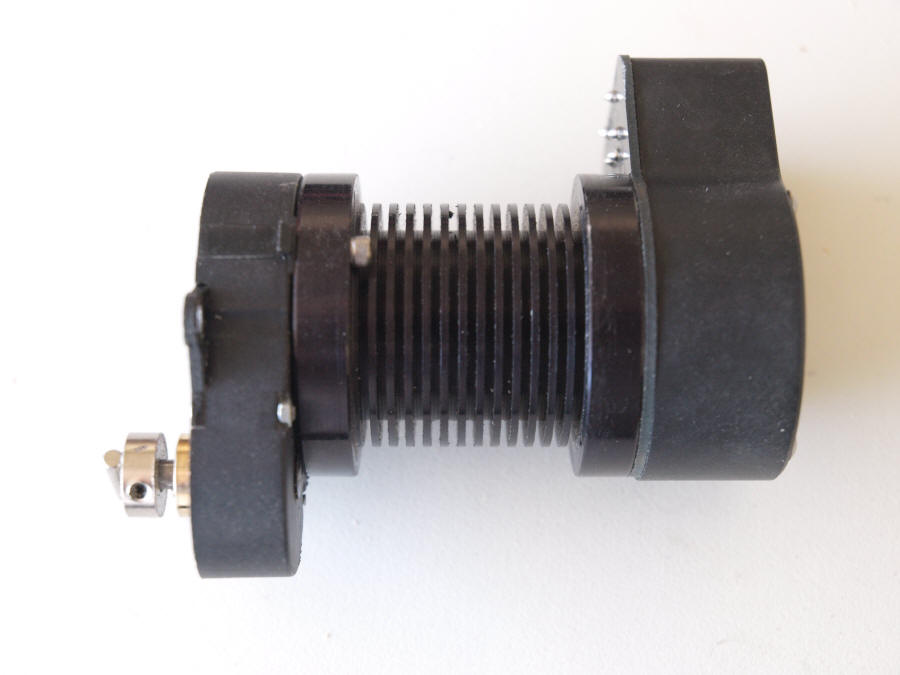

Fig 1 Unmodified gearbox (this one is 5 years old)

Fig 2 These Plastic Dimples will be replaced

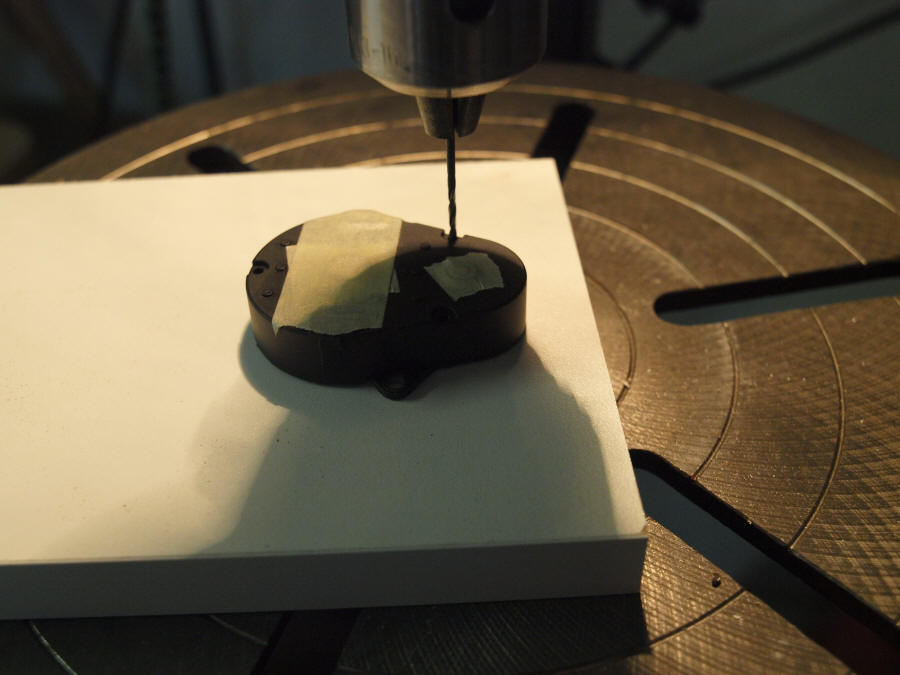

I started off by masking off all the holds that would not be used, to make sure no debree got into the gearbox, and also made sure I did not drill out the wrong holes. Now I did only one hole at a time and completely finished that hole before starting on the next. This was it insure that the gearbox did not come apart, or shift alignment. See Fig 3 below. images of inside the grearbox below.

Fig 3

Fig 3

Use a drill press with a 5/64" drill bit, if possible, to drill out the first hole. See Fig 4. Use a peace of wood with a 1/2 hole in it to allow for the shaft of the gearbox to be down, and as a backer to the drill table. Do one hole at a time.

Fig 4

Then the screw hole has to be countersunk. I used a small countersink tool, to make sure I had the proper 60 Degree angle for the countersink. Drill bits do not provide the proper countersink angle, and on something this precise, it would be better it do it correctly. I also used the tool by hand. The plate is some type of metal.

Fig 5

Here is a couple of images showing the first hole with the screw and nub in it.

Fig 6

Fig 7

Fig 8 With Maxom Motor attached.

Fig 9 With Maxom Motor attached.